On July 10,2025,our company business staff received a case from a client, which required us to complete the full production process--from design development,mold making to mass production within one and a half months based on a vague sketch provided by the client.The sketch was drawn arbitrarily by the client without any feasibility analysis,and the products has not undergone feasibility verification.We need to help them complete the feasibility reference and production process matching design based on our own production experience.

The client’s drawings presented all dimensions and angles as vague concepts. Initially,the design team was uncertain about the feasibility of the product for actual production. Typically,clients provide complete 3D drawings,such as for wine openers,wine stoppers and garlic presses,which are already validated for production feasibility. In such cases,we only need to directly develop molds based on the client’s 3D specifications.For example,in 2024,a Spanish client provided a 3D drawing for a wine opener, and we swiftly developed the mold for a component part,achieving mass production and market launch within one month.

The challenge with the four measuring spoons for U.S. client this time lies in the absence of precise 3D drawings to calculate costs.Without knowing whether the client would accept the product’s cost,there is a risk of incurring upfront design costs that may not be recoverable.

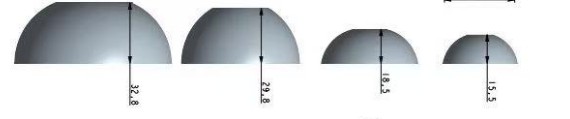

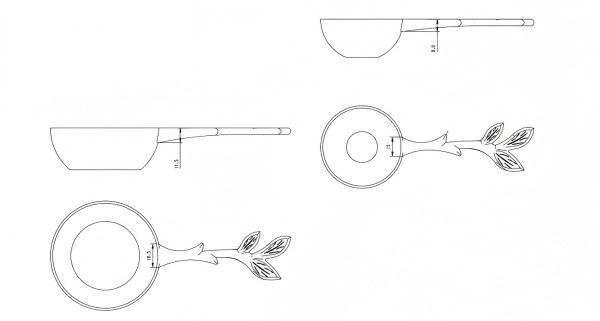

First, involved assessing the product’s shape and potential usage based on prior experience.Using zinc alloy as the primary material,we calculated material density and surface characteristics,incorporated ergonomics and designed the overall dimensions for the four measuring spoons or ice spoons.Subsequently,we refined each curve,R-radius angles and other small-scale details based on these dimensions.

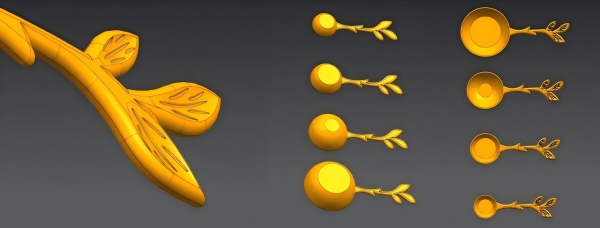

Using zinc alloy material for this type of product enhances its overall shape to be more rounded and less rigid,while also aligning more closely with the client’s desire for a retro surface finish. Additionally,zinc alloy facilitates easier manufacturing and reduces production costs.The yellow drawing provided is the final design schematic from Hanjia Company.Due to confidentiality requirements,no specific dimensions are marked in this document.

Second,we communicated with the U.S. client after the product’s 3D design was finalized. The client initially approved the design drawings,allowing us to proceed with surface color confirmation and processing method design.We provided three retro colors previously used for other clients,and after careful consideration,the client selected red antique copper. Based on our recommendation,a brushed finish was applied to enhance the product’s retro aesthetic.

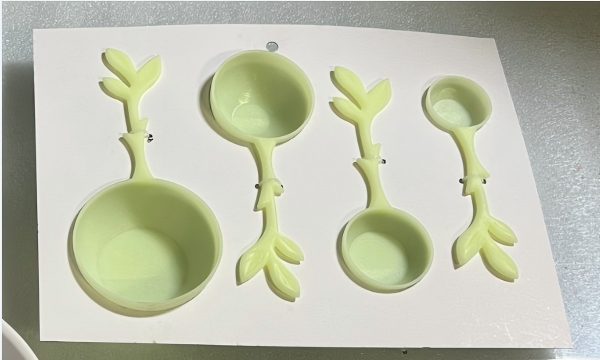

Third,after the preliminary design of the product specifications,process flow, manufacturing methods and cost calculations were finalized,we carried out 3D prototyping.We then discussed details with the client,signed the mold development contract and confirmed the manufacturing cost.

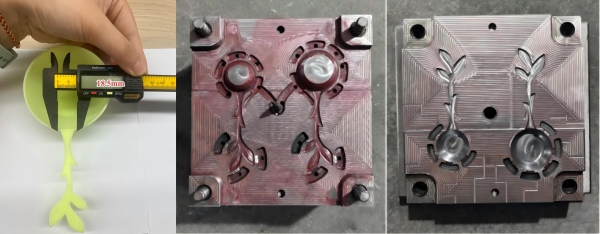

After over a month of intensive design work,sample making and iterative discussions with the client,we completed the collaborative refinement of product drawings.This enabled us to swiftly produce the molds required for mass manufacturing and create actual samples, allowing the client to promptly confirm the prototype.

On August 18, 2025,we completed the final vintage color sample and secured the client's final approval,officially entering the mass production phase.The client had previously specified that all pre-production details needed to be confirmed within two months when the four spoon product concepts were initially proposed.To ensure the client could meet their sales schedule,we completed all necessary pre-production tasks in just 38 days, earning the client's high praise.The client was ultimately very satisfied with the product's design dimensions,shape aesthetics and vintage surface color finish.

To achieve the vintage color finish for this project,both our team and the client faced significant challenges.While the brushed finish on the exterior was relatively straightforward,the internal structure presented a complex issue.In order to match the exterior's vintage aesthetic on the interior,our sample technicians engaged in extensive negotiations with the plating factory.Through these efforts,the plating subcontractor invested in process improvements to achieve the desired finish,resulting in the final product appearance as shown in the images.This collaboration successfully realized the client's vision and ensured the product met all quality requirements.

Jinhua hanjia commodity co.,ltd is dedicated to serving clients and resolving all their challenges.We provide swift and efficient solutions,ensuring clients feel as if we were their own manufacturing workshop,offering professional and flawless collaboration to eliminate any concerns.With years of experience in product design and development,we can deliver the most professional advice and references at any time.Over the years,we have designed and developed hundreds of diverse types of home and daily living products for clients around the world,including kitchen gadgets,dining utensils and alcohol-related tools and bottle openers,using materials such as stainless steel and zinc alloy.We believe we can offer clients the highest quality development and production services.Welcome clients to provide designs, ideas, sketches or any brain-inspired concepts.Let us help bring them to life.